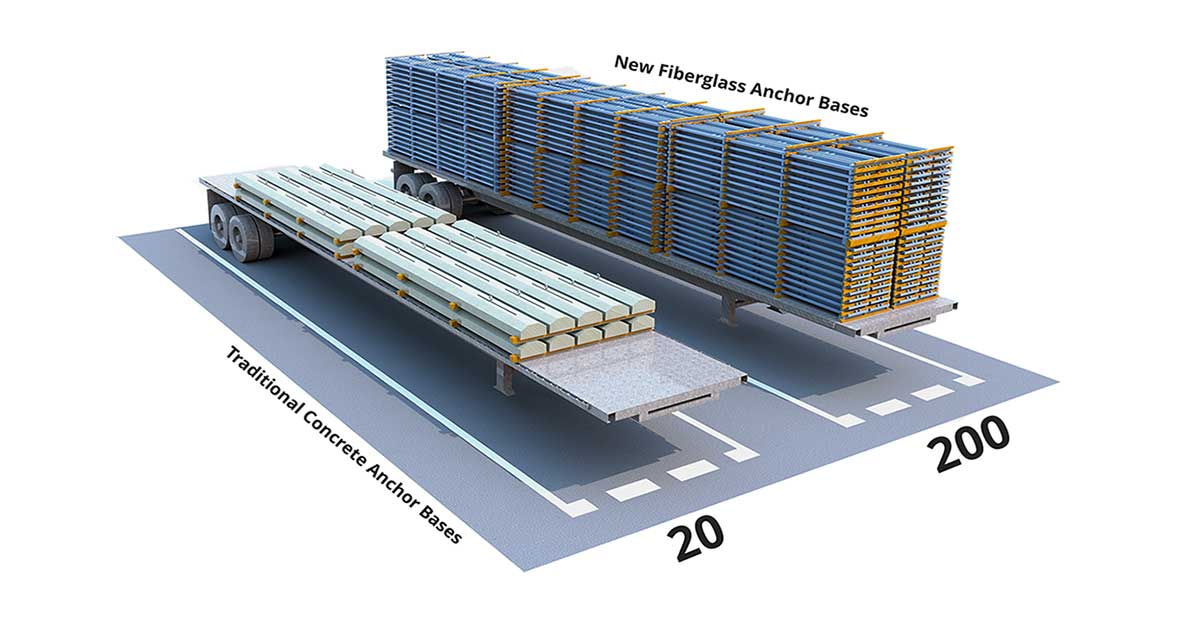

The electric revolution is gaining momentum, and at its core are the advancements in materials technology, particularly the fiberglass dielectric properties, which are powering the future of electric cars.

Fiberglass holds a pivotal role in the Electric Vehicle (EV) industry, with its importance continuing to grow, due to its lightweight strength, dielectric properties, corrosion resistance, design flexibility, and environmental benefits. It not only contributes to the development of efficient and durable electric vehicles but also supports the expansion of charging infrastructure, thereby accelerating the growth of the electric mobility sector. As the EV industry continues to evolve, fiberglass innovations are expected to play an increasingly significant role in shaping its future. In this blog post, we’ll explore some important parts in the ecosystem of EVs that are made of fiberglass and also why fiberglass parts are crucial for the growth of electric cars and their associated charging network.

Fiberglass Parts: from Electric Cars, the Electric Distribution Network, and Charging Stations

Fiberglass is commonly used in several key components and areas due to its fiberglass dielectric properties, among other advantages:

- Battery Enclosures: Fiberglass is utilized for manufacturing battery enclosures or trays in electric vehicles. These enclosures protect the sensitive battery cells from external elements, ensuring safety, and provide thermal insulation.

- Charging Station Housings: Many charging stations feature fiberglass housings or enclosures. These housings protect the electrical components, connectors, and charging cables from environmental factors like rain, dust, and UV radiation. Fiberglass provides durability and weather resistance.

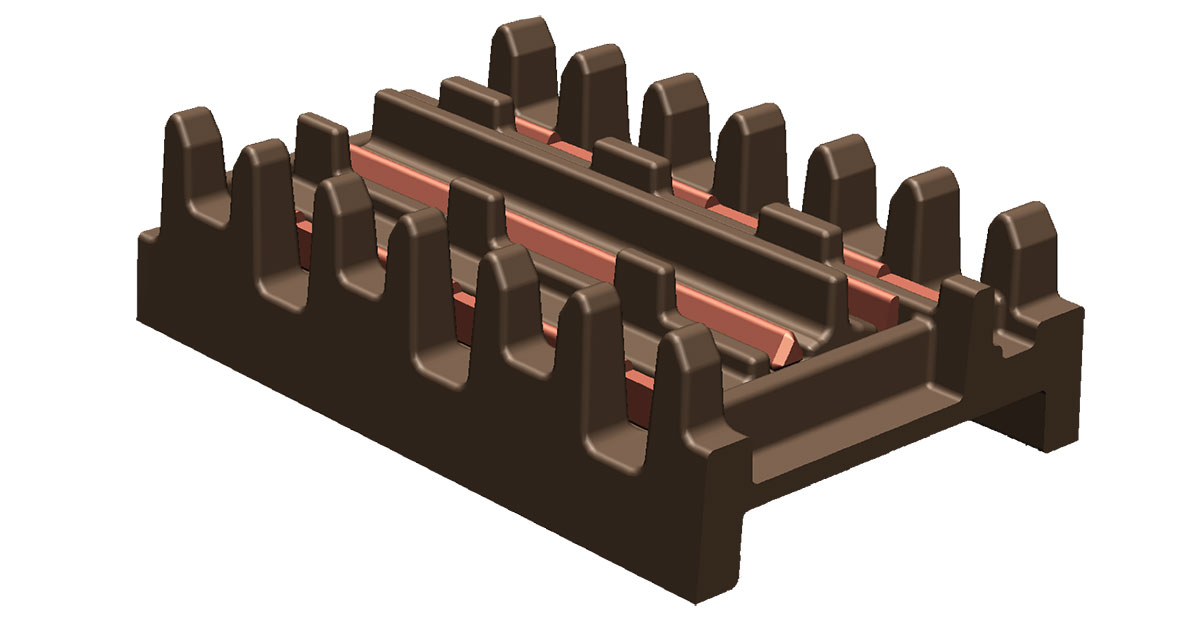

- Wiring Harness Insulation: Fiberglass can be used for insulating and protecting wiring harnesses within electric vehicles. Its dielectric properties prevent electrical interference and ensure the safe transmission of power.

- Charging Connector Handles: Some charging connectors and handles are made from fiberglass-reinforced plastics (FRP). Fiberglass enhances the strength and durability of these components while maintaining electrical insulation.

- Charging Station Structures: In larger charging stations, structural components and support structures can be constructed using fiberglass materials. These structures provide stability and can withstand exposure to outdoor conditions.

- Charging Station Bollards: Bollards, which protect charging stations and help guide vehicles during charging, can be made from fiberglass composites. Fiberglass bollards are lightweight, durable, and resistant to corrosion.

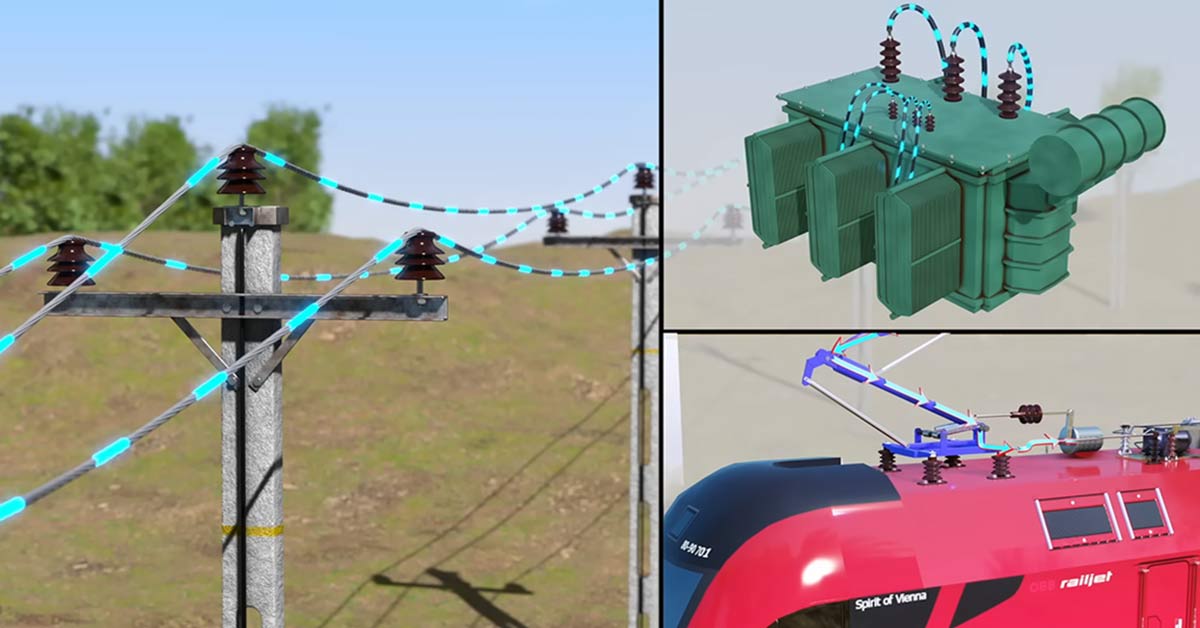

- Insulators: Within the electric distribution network, fiberglass is used in insulators. These insulators provide electrical separation and prevent short circuits in high-voltage transmission and distribution lines.

- Enclosures for Electrical Equipment: Various electrical equipment used in both electric vehicles and charging stations may have enclosures or casings made from fiberglass. These enclosures protect internal components from mechanical damage and environmental factors.

Fiberglass offers a combination of lightweight strength, electrical insulation properties, corrosion resistance, and design flexibility, making it suitable for these critical applications in electric mobility and charging infrastructure. Its use contributes to the safety, efficiency, and longevity of electric vehicles and the charging network.

Why Fiberglass?

The fiberglass dielectric properties make it an invaluable material in the electric mobility sector for several reasons:

- Lightweight Dielectric Strength for Electric Mobility:

Fiberglass materials are prized for their exceptional dielectric strength alongside their lightweight nature. In the world of EVs, where maximizing energy efficiency is paramount, shedding unnecessary weight while maintaining excellent electrical insulation is a top priority. Fiberglass components make this possible. Their lightweight property reduces the overall weight of the vehicle, enhancing its energy efficiency and extending the driving range. This weight reduction is particularly vital in electric cars, where every kilogram saved contributes to better battery performance and longer journeys.

The dielectric strength of fiberglass materials ensures that electrical currents are effectively insulated and prevented from arcing or causing electrical breakdowns. This property is crucial in EVs, as these vehicles rely heavily on advanced electrical systems and high-voltage components. Fiberglass parts contribute to the safety and reliability of these systems by providing excellent insulation against electrical leaks and short circuits.

- Versatile Dielectric Applications in EVs:

Fiberglass materials with outstanding dielectric properties find application throughout electric vehicles, from the chassis to the body and interior components. One prominent use is in the manufacturing of battery casings and protective shields. The robust and dielectric nature of fiberglass provides a secure electrical enclosure for lithium-ion batteries, ensuring safety and preventing electrical interference.

Additionally, fiberglass parts are employed in the production of EV body panels. The lightweight yet dielectric characteristics of fiberglass make it an ideal choice for exterior components, reducing the overall vehicle weight and improving aerodynamics. As EV manufacturers strive to enhance energy efficiency and range, fiberglass with exceptional dielectric properties plays a pivotal role in achieving these goals while maintaining electrical safety.

- Charging Equipment with Dielectric Excellence:

Electric vehicles wouldn’t be complete without an extensive network of charging stations, and fiberglass materials are also making their mark in this domain. Charging station infrastructure requires durable and dielectric components to ensure the safe transfer of electrical power. Fiberglass enclosures and covers with excellent dielectric strength provide reliable protection for the charging equipment, preventing electrical hazards.

Moreover, fiberglass organosheets with outstanding dielectric properties are used in the production of charging station housings. These sheets are known for their exceptional molding capabilities, enabling the creation of complex, aerodynamic designs that optimize airflow around the charging stations. The result is more efficient cooling of the charging equipment, which is vital for maintaining charging speeds and ensuring the longevity of the station, all while upholding dielectric safety standards.

- A Sustainable Future with Dielectric Insulation:

Beyond their mechanical and dielectric advantages, fiberglass parts contribute to the sustainability of the electric vehicle industry. These materials are inherently eco-friendly, as they can be recycled and repurposed. As the EV market continues to grow, the use of sustainable materials with exceptional dielectric properties becomes increasingly important, aligning with the industry’s commitment to reducing its environmental footprint.

Conclusion

Fiberglass materials with exceptional dielectric properties have emerged as a driving force behind the growth of electric cars and their charging infrastructure. Their lightweight dielectric strength, versatility, and eco-friendly properties make them an ideal choice for a sustainable, energy-efficient future. As electric vehicles become more prevalent on our roads, fiberglass components with outstanding dielectric insulation will continue to play a pivotal role in shaping the transportation landscape, making clean, green mobility a reality for all while ensuring electrical safety and reliability.

Pultrusion Technique Inc. is a pioneer in the pultrusion industry, dedicated to crafting custom-made fiberglass parts of the highest quality, surpassing industry standards. With a commitment to innovation, precision engineering, and environmentally sustainable practices, we empower the electric sector, be it for EVs and charging station manufacturers or other applications to push the boundaries of what’s possible. By consistently delivering superior fiberglass components, we ensure that electric properties of our parts not only meet but exceed performance expectations. In a rapidly evolving landscape where technology and sustainability converge, our unwavering dedication to excellence places us at the forefront of driving the future of electric industry and distribution networks. When you choose Pultrusion Technique Inc., you choose durability, reliability, and a greener tomorrow.