Innovative

composites

engineering

Why

Pultrusion Technique?

Main sectors of activity

UNDERGROUND STORAGE TANKs

Non-ferrous metal refining

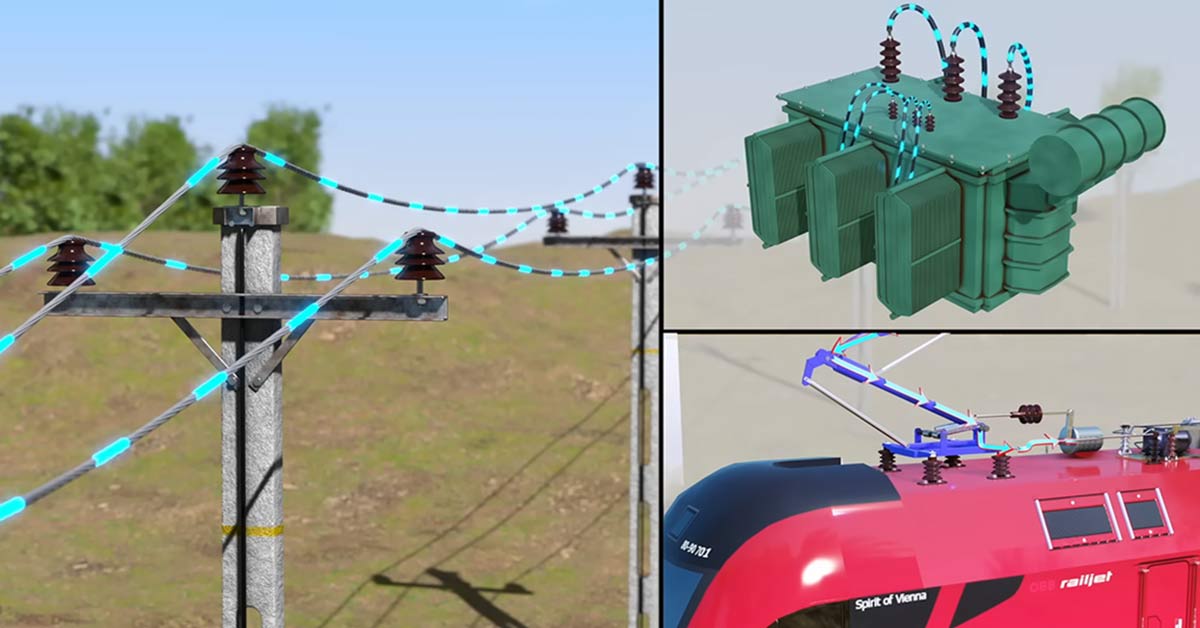

Electricity

Pultruded parts and composites

UNDERGROUND STORAGE TANKs

Non-ferrous metal <br/>refining

Electricity<br/><br/>

Pultruded parts and composites

- WHAT CLIENTS SAY

Personalized

Customer Experience

Composite materials continue to offer innovative alternatives to current technical needs. We are able to design and manufacture a customized solution that will meet your needs, regardless of the industry.

About us

Pioneer in the industry since 1966, Pultrusion Technique is a major player in the development of fiber-reinforced polymer (FRP) composites. Our products are protected by numerous patents, and some exceed international standards. They are the most efficient, robust, resistant, durable and cost-efficient in the market, and serve diverse industries (mining, petroleum, transportation, construction and electricity).

Some of our many satisfied clients

What is pultrusion?

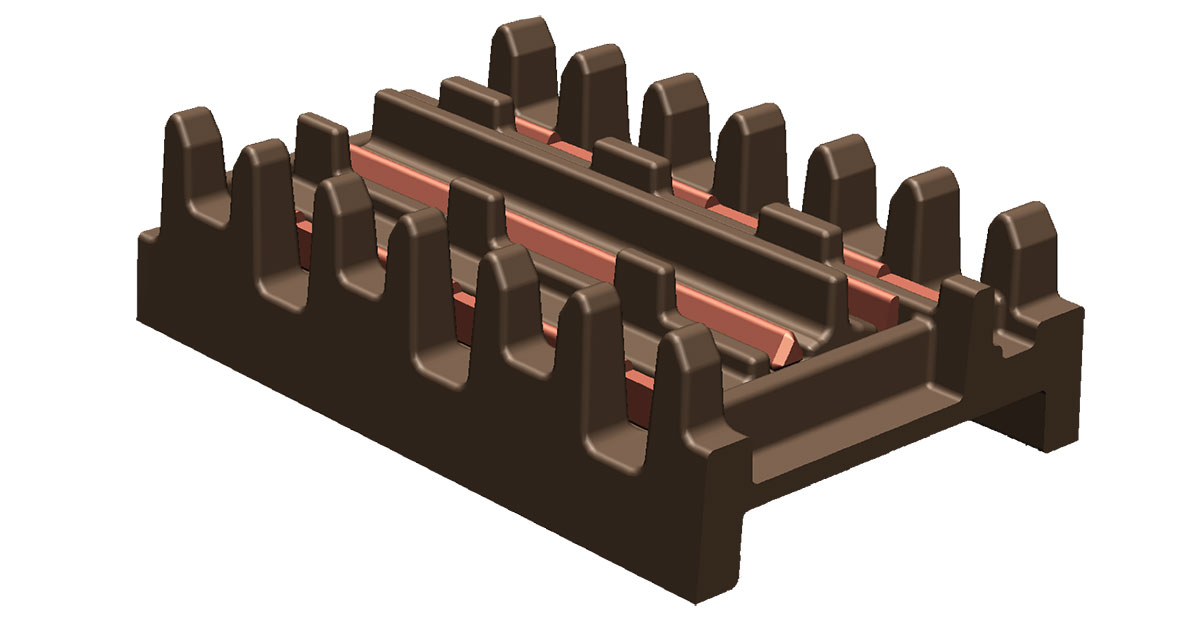

Pultrusion is a continuous process for manufacturing

high-strength light-weight structural parts of continuous length composite profiles, with uniform cross-sections.

During the process, fiberglass reinforcement is aligned lengthwise and impregnated with resin, pulled through a heated die and moulded to desired shape.

Special Features

Countless possibilities

Complex geometries

Superior mechanical properties

High strength

Endurance

Unmatched performance

Resistance to corrosion

Very accurate fiber orientation and a high rate of reinforcement

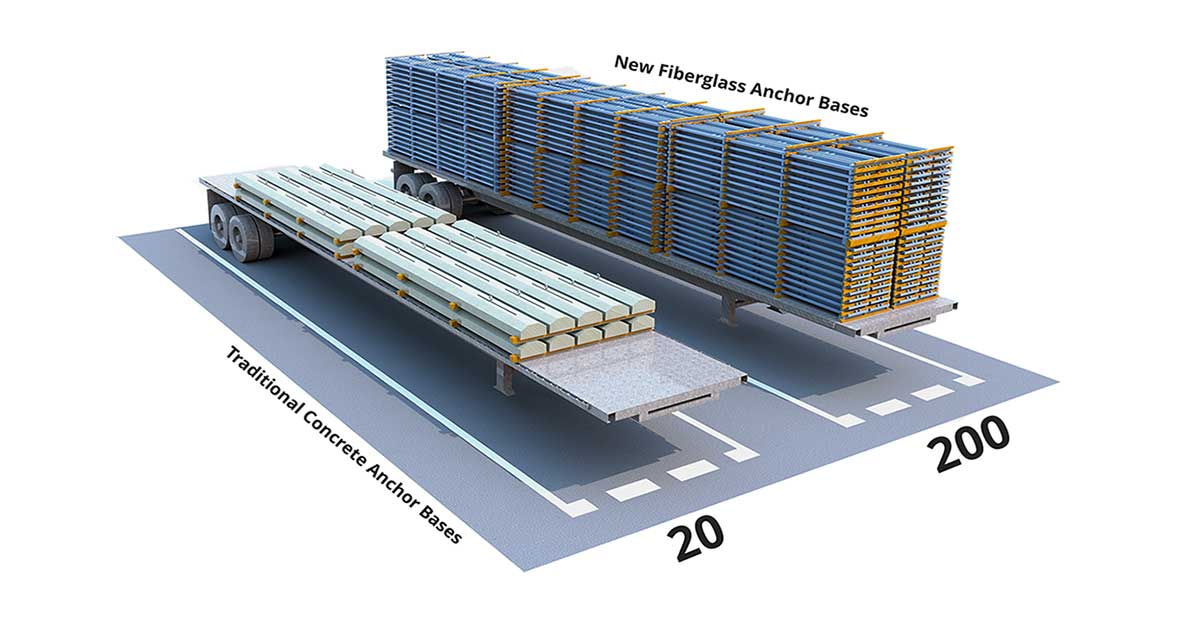

Lightweight

Durability

Impermeability

Minimal maintenance

Versatility

Low conductivity

Electromagnetic neutrality

Easy installation

Many industries have found Pultruded Products to be the best option that assures them of little or no maintenance, and more economic even considering the extra upfront cost.

Special Features

Countless possibilities

Complex geometries

Superior mechanical properties

High strength

Endurance

Unmatched performance

Resistance to corrosion

Very accurate fiber orientation and a high rate of reinforcement

Lightweight

Durability

Impermeability

Minimal maintenance

Versatility

Low conductivity

Electromagnetic neutrality

Easy installation

- recent articles

Research and

development

research and development of the pultrusion process