In today’s rapidly evolving world, the demand for electricity is greater than ever before. As industries grow, technology advances, and electric vehicles become the norm, the need for efficient and reliable power transmission networks is paramount. Traditional materials are being reimagined to meet these demands, and at the forefront of this transformation is pultruded fiberglass. This remarkable material is playing a pivotal role in revolutionizing electricity power transmission networks, offering numerous applications that enhance performance, safety, and sustainability.

The Power of Pultruded Fiberglass

Pultruded fiberglass, also known as fiberglass-reinforced polymer (FRP), is a composite material composed of fine glass fibers embedded in a polymer matrix. This unique combination of materials results in a product that boasts exceptional mechanical and electrical properties. Here’s why pultruded fiberglass is making waves in the electrical industry:

- Electrical Insulation:

One of the standout qualities of pultruded fiberglass is its excellent electrical insulation. This property is vital in power transmission networks, where preventing electrical discharge and maintaining a high dielectric strength are essential for safety and reliability.

- Mechanical Strength:

Fiberglass rods and profiles exhibit impressive mechanical strength. They can withstand the stresses associated with power transmission, including wind, ice, and mechanical loads. Their high tensile strength ensures long-lasting performance, reducing the need for frequent maintenance and replacements.

- Corrosion Resistance:

Unlike traditional materials like steel or wood, pultruded fiberglass is highly resistant to corrosion, even in aggressive environments. This resistance prolongs the lifespan of components, minimizing downtime and maintenance costs.

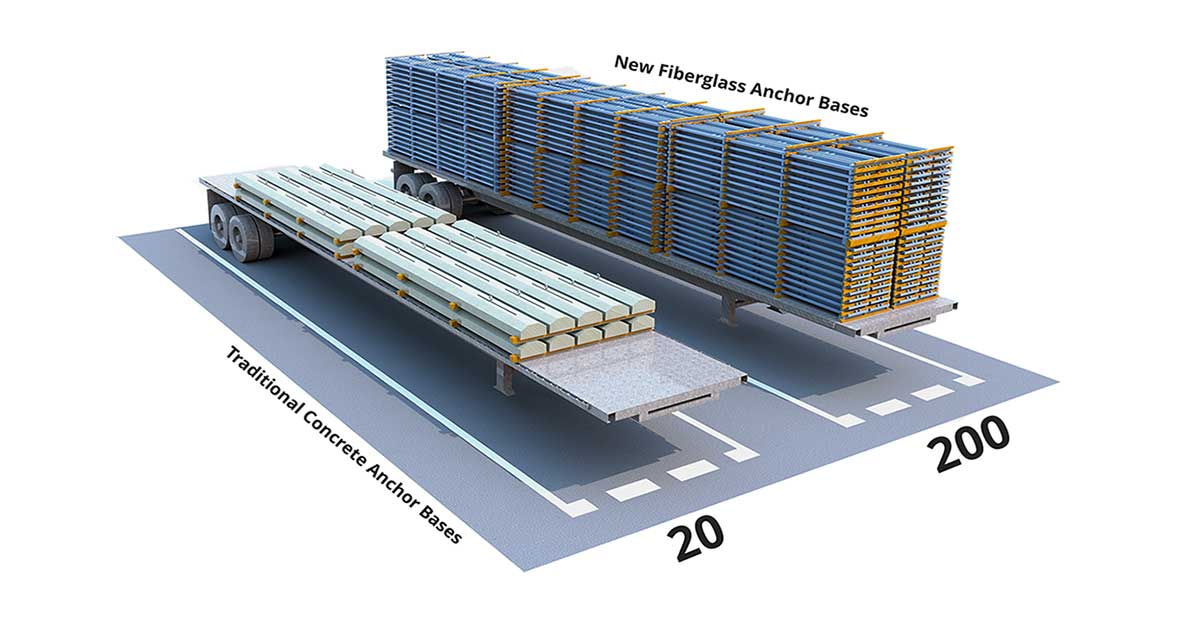

- Lightweight Design:

Fiberglass is exceptionally lightweight, making it easier to handle during installation and maintenance. This characteristic not only reduces labor costs but also enhances safety, as heavy materials pose a higher risk of accidents during handling.

Applications in Electricity Power Transmission Networks

Pultruded fiberglass is finding applications across various segments of electricity power transmission networks, contributing to efficiency, reliability, and sustainability:

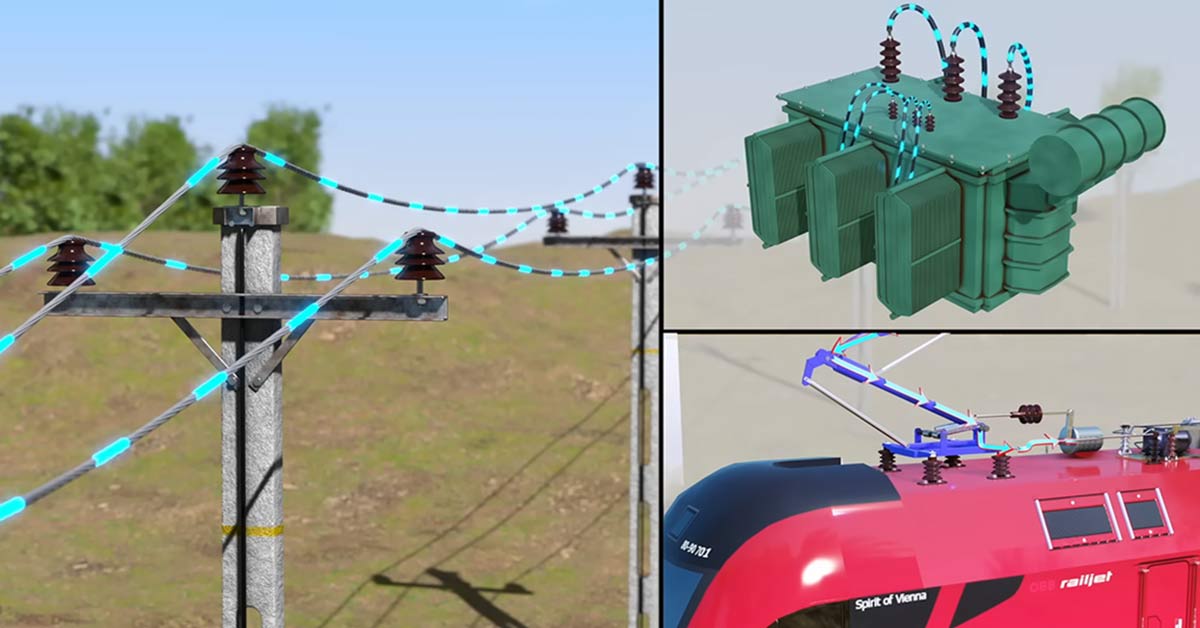

Insulators: Insulators made from fiberglass rods offer high electrical resistance and mechanical strength. They prevent current leakage and provide support for overhead power lines. Their lightweight design simplifies installation and maintenance.

Crossarms and Brackets: Fiberglass crossarms and brackets provide sturdy support for power lines. Their corrosion-resistant properties ensure longevity, even in harsh outdoor conditions.

Guy Strain Insulators: Guy strain insulators play a crucial role in stabilizing power transmission towers. Fiberglass-based insulators offer superior electrical performance and mechanical durability.

Transformer Bushings: Fiberglass transformer bushings offer electrical insulation and resistance to moisture, ensuring the safe and reliable connection of transformers to the power grid.

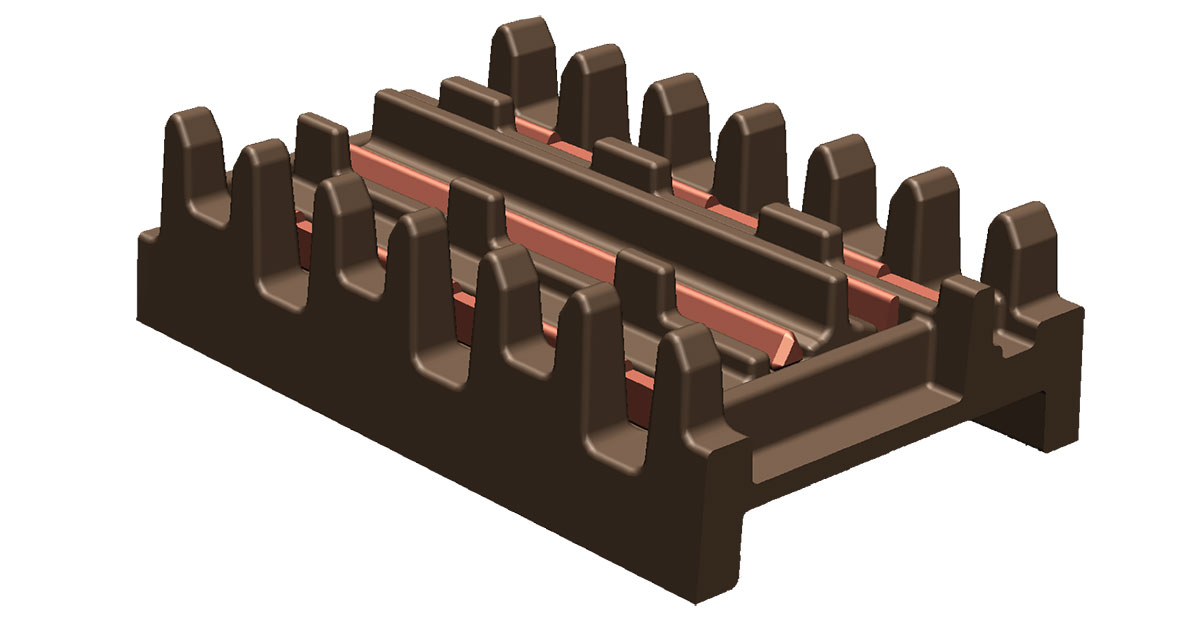

Cable Trays and Supports: In substations and along transmission lines, fiberglass cable trays and supports organize and protect electrical cables. They resist corrosion and provide electrical insulation.

Switchgear Components: Components for switchgear cabinets and enclosures made from fiberglass offer electrical insulation, thermal stability, and resistance to arc flash, enhancing safety and reliability.

Insulating Crossarms for Substations: Insulating crossarms made from fiberglass support busbars and other electrical components in substations. They prevent electrical tracking and ensure safe substation operations.

Lightning Arrestors: Fiberglass rods can serve as supports for lightning arrestors, protecting power equipment from lightning-induced damage.

Composite Poles: Some power utilities have adopted composite poles made from fiberglass-reinforced materials. These lightweight poles are durable and corrosion-resistant, making them ideal for various applications in transmission and distribution lines.

Transmission Tower Components: Ladder rungs, platform grating, and hardware made from fiberglass are used in the construction and maintenance of transmission towers. They offer electrical insulation and resistance to environmental factors.

At Pultrusion Technique, we are proud to be pioneers in the pultrusion industry, producing pultruded fiberglass elements that exceed market standards. Our commitment to quality and innovation ensures that our products are the ideal choice for diverse applications in the electrical industry. We understand the critical role that materials play in enhancing power transmission networks, and we are dedicated to providing solutions that promote efficiency, safety, and a greener future.

As the world’s hunger for electricity continues to grow, the need for advanced materials like pultruded fiberglass becomes increasingly evident. By harnessing the power of this remarkable composite, the electrical industry can build more resilient, sustainable, and reliable power transmission networks, ensuring that the lights stay on for generations to come. The future of electricity is brighter than ever, and pultruded fiberglass is leading the charge.