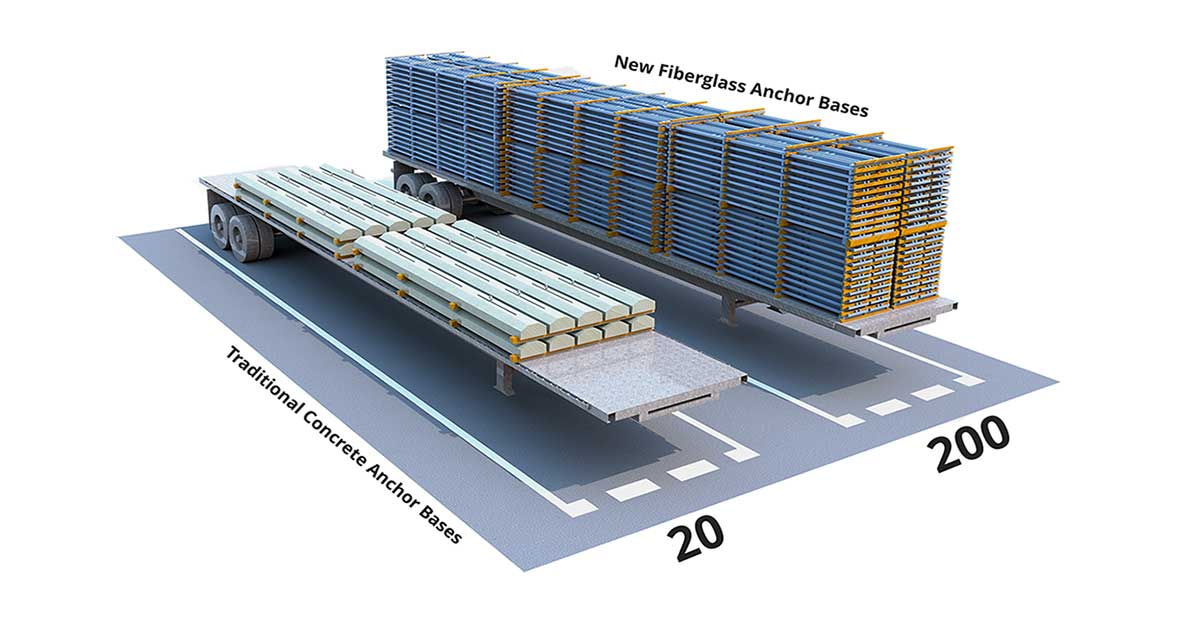

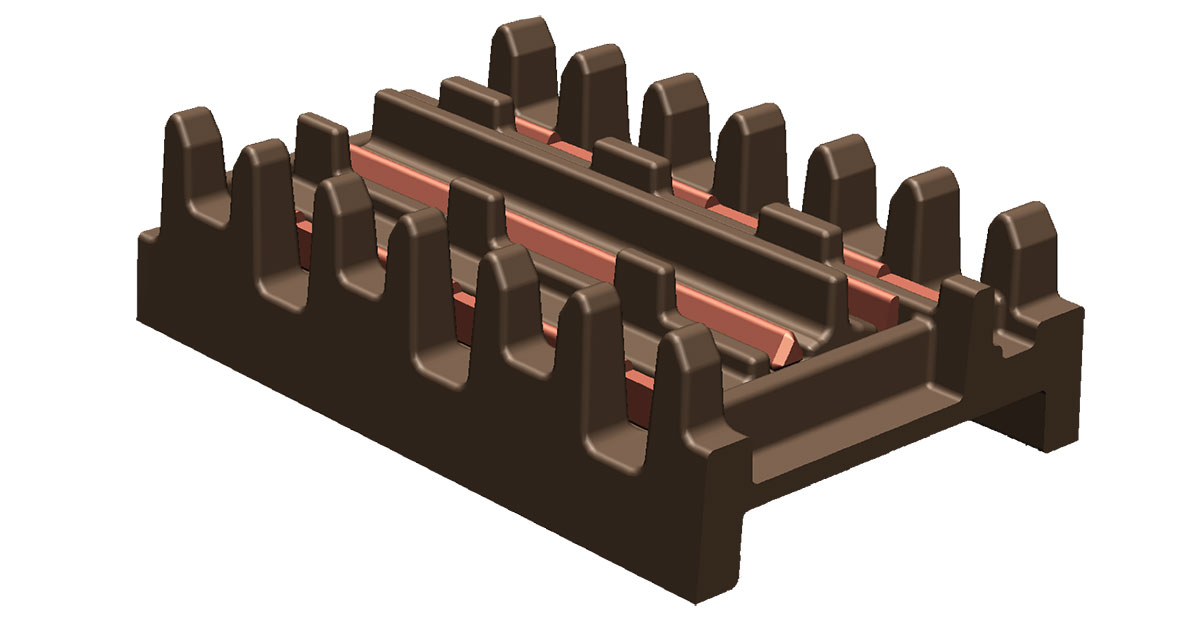

Underground storage tanks are a critical component of many industries, used for storing fuels, chemicals, and other liquids. Traditional concrete anchor bases have been a common solution for anchoring underground storage tanks, but they come with several disadvantages in terms of weight, installation time, and overall efficiency. The F.A.S.T. (Fast Anchoring System for Tanks) is an innovative anchoring system designed to address all these. This system is made of lightweight and rigid fiberglass composite deadman anchors that beats all other alternatives in the market in terms of performance and efficiency. Within the last few years of development, the engineering team at Pultrusion Technique Inc. has frequently revised the design of the F.A.S.T. system to achieve its unique features, taking into account the safety factors and the factor of safety for the product under applied loads.

Advantages of composite deadman anchors (F.A.S.T.). over competitors’ products.

The F.A.S.T. system’s innovative design ensures not only increased performance and efficiency but also prioritizes the safety of workers during the installation process. The ability to ship the system preassembled with the tank on the same truck is a significant advantage. It eliminates the need for workers to manually lift the deadman into the excavation, reducing the risk of injury and strain.

Additionally, the “one-step-fix” method simplifies the installation process, allowing workers to move the tank and attachment into the hole with ease.

The lightweight fiberglass deadman also allows for the composite deadman anchor system to be assembled beside the tank before the installation, removing all safety concerns for workers by eliminating the need for workers to enter the excavation. The ability to assemble the system in this way not only makes the installation process more efficient but also safer for workers. As a result, the F.A.S.T. system is an excellent option for underground storage tank anchoring, offering enhanced safety measures and increased efficiency.

Development Process.

The F.A.S.T. system has undergone several design revisions to meet the project requirements and address challenges during the prototype manufacturing. Design revisions were made to optimize the weight of the product while providing ultimate resistance against the applied loads. Moreover, some parts were alternated with more economical materials, and some design elements were redesigned to simplify the manufacturing process to save labor costs.

The design has been then evaluated both numerically and experimentally in different loading stages, and lifting tests have been conducted on fiberglass deadman loaded with sandbags to validate the calculated results.

It is worth mentioning that a case study installation was done more than two years ago, and the results confirmed the exceptional time savings during installation as well as the performance of the fiberglass anchor bases in securing the underground tank. Despite the water table at the installation zone going above the ground level several times since then, the composite deadman anchor system has proven to be effective in securing the underground tank.

Summary.

In summary, the F.A.S.T. system is an innovative anchoring solution that offers several advantages over traditional concrete anchor bases. Its lightweight design makes it easy to handle and install, reducing the risk of injury and strain for workers during the installation process. The ability to ship the system preassembled with the tank on the same truck also makes it more cost-effective and environmentally friendly. The F.A.S.T. system has undergone several design revisions to ensure optimal performance and safety, and its durability and long-lasting performance have been proven in case study installations. As a result, the F.A.S.T. system is an excellent option for underground storage tank anchoring, offering enhanced safety measures, increased efficiency, and cost-effectiveness.